Surgical Scissors by Rhein Group: Precision

for Every Cut

Each cut counts when it comes to surgery. Opening tissue layers, cutting sutures, or dissecting sensitive structures, the ideal pair of surgical scissors makes the difference between accuracy and complication. At Rhein Group, we are experts at creating scissors surgeons can rely on—providing the best combination of sharpness, balance, and comfort.

In this guide, we delve into Rhein Group’s entire portfolio of surgical scissors, their various uses, and why our instruments are selected by top healthcare institutions globally.

The Important Role of Surgical Scissors in Medical Practice

Scissors are more than cutting instruments—they’re an extension of a surgeon’s vision and handiwork. The slightest imbalance in the blades, weight, or handle can be detrimental to surgical success.

That’s why Rhein Group manufactures scissors surgical instruments that:

Provide clean, accurate cuts

Lessen tissue trauma

Lessen surgeon fatigue with extended use

From neurosurgery craniotomy scissors to gynecology episiotomy scissors, Rhein provides each instrument to the highest standards of quality and performance.

Surgical Scissors Types by Rhein Group

We have a wide range of scissors designed for various surgical procedures. Here’s a detailed overview:

1. Mayo Scissors (Straight & Curved)

Category: General Surgery

Main Use: Cutting sutures, fascia, and tough tissues

Mayo scissors are known for their strength and durability. The straight type is typically used for cutting sutures and materials, while the curved version is ideal for dissecting dense tissues. Their robust design makes them a staple in most surgical sets.

2. Metzenbaum Scissors (Straight & Curved)

Category: General Surgery

Main Use: Cutting sutures, fascia, and tough tissues

Mayo scissors are known for their strength and durability. The straight type is typically used for cutting sutures and materials, while the curved version is ideal for dissecting dense tissues. Their robust design makes them a staple in most surgical sets.

3. Iris Scissors

Category: General / Ophthalmic

Main Use: Precise cutting in small surgical fields

Originally designed for ophthalmic surgery, iris scissors are now widely used in various specialties for their fine, sharp blades. They allow precision in small or confined surgical spaces.

4. Lister Bandage Scissors

Category: General Surgery

Main Use: Cutting bandages and dressings safely

Lister scissors feature a blunt end that slides under bandages without harming the skin, making them ideal for post-surgical care and first aid. They’re essential for safely removing dressings.

5. Tenotomy Scissors

Category: General Surgery

Main Use: Fine dissection of soft tissue

Lister scissors feature a blunt end that slides under bandages without harming the skin, making them ideal for post-surgical care and first aid. They’re essential for safely removing dressings.

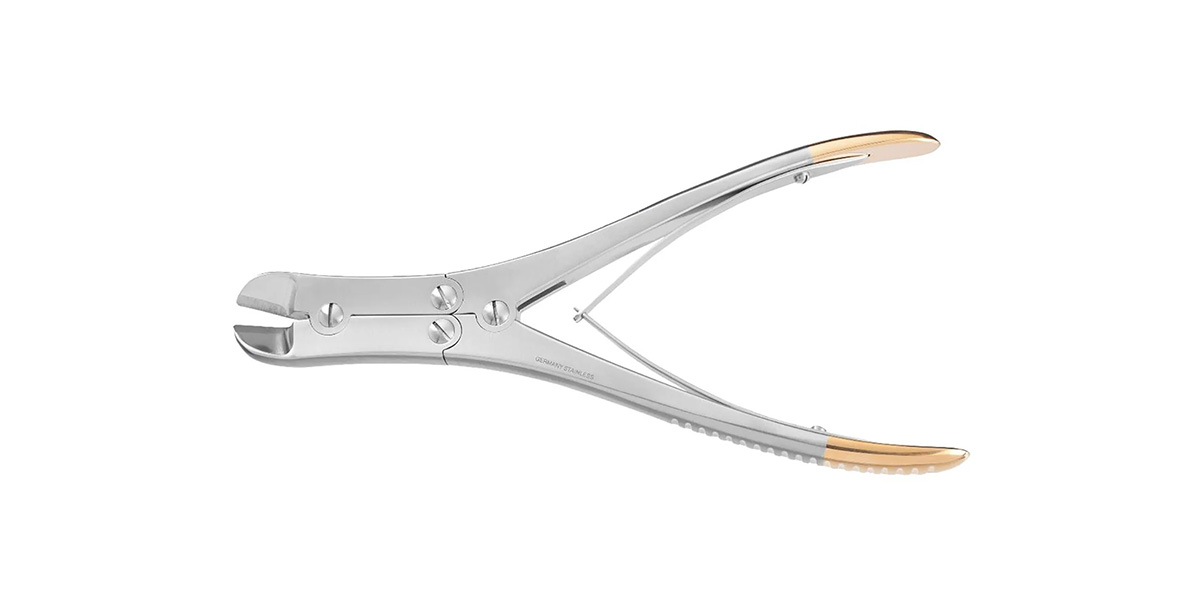

6. Brun Bone Cutting Scissors

Category: Orthopedic

Main Use: Cutting small bones and cartilage

These heavy-duty scissors are designed for orthopedic procedures. With strong jaws, they can cut through small bones and cartilage, making them vital for bone-related surgeries.

7. Wire Cutting Scissors (Orthopedic Pin/Wire Cutters)

Category: Orthopedic

Main Use: Cutting orthopedic wires and pins

Specialized for orthopedic use, wire cutting scissors are designed to cut through metal pins and wires used in fixation procedures. Their robust build ensures efficiency without damaging the surrounding area.

8. Spencer Stitch Scissors

Category: Orthopedic / General

Main Use: Removing sutures efficiently

Spencer scissors have a small hook on one blade, allowing easy lifting and cutting of sutures. They are widely used in both general and orthopedic settings for suture removal.

9. Castroviejo Micro Scissors

Category: Microsurgery (Vascular/Neuro/Plastic)

Main Use: Fine dissection under a microscope, vessel work

Castroviejo scissors are designed for precision at the microscopic level. They are widely used in vascular, neurosurgical, and plastic surgeries where delicate tissue and vessel work is required.

10. Vannas Scissors

Category: Microsurgery (Ophthalmic/Neuro)

Main Use: Precision cutting in delicate microsurgery

Vannas scissors are ultra-fine and sharp, making them indispensable in ophthalmic and neurosurgery. Their design allows for highly precise cutting in extremely delicate procedures.

Why use Rhein Group for Surgical Scissors?

- German Stainless Steel & Titanium Options: For longevity and accuracy

ISO 13485, CE Marking, and FDA Registration: For assurance of compliance worldwide

Extensive Range: From scissors deployed in surgery to scissors deployed in labs

Innovation-Driven: Personalized designs for laparoscopic, endoscopic, and microsurgical disciplines

Every instrument goes through strenuous quality control, from the cutting edge sharpness to the calibration of blade tension.

Surgeon Testimonials

Global Manufacturing Standards for Surgical Instruments

1. ISO 13485: Medical Devices Quality Management Systems

Purpose: Defines requirements for a medical device-specific quality management system.

Why it matters: Guarantees that equipment complies with regulatory requirements, patient safety, and uniform quality.

How it’s implemented:

Documentation of production and design processes

Risk management and traceability systems

Regular internal and third-party audits

2. CE Marking (European Conformity)

Required for: Sale of surgical instruments in the European Union (EU) and European Economic Area (EEA).

Indicates: Conformity to EU Medical Device Regulations (MDR).

Ensures:

Biocompatibility

Sterilization validation

Safety during intended use

3. FDA 21 CFR Part 820 (U.S. FDA Quality System Regulation)

Applicable to: Manufacturers selling in the United States.

Aims at: Quality assurance, validation, and complaint handling.

What it covers:

Device Master Records (DMRs)

Corrective and Preventive Actions (CAPA)

Inspection and testing procedures

4. ASTM & ISO Material Standards

ASTM F899: Standard for stainless steel used in surgical instruments.

ISO 7153-1: Defines corrosion-resistant steel and alloys for instruments.

Rationale: Guarantees materials:

Withstand repeated sterilization

Don’t corrode, rust, or cause tissue damage

Retain sharpness and structural integrity

5. RoHS & REACH Compliance (European Market)

RoHS: Prohibits use of hazardous materials in electronics and materials.

REACH: Guarantees chemicals used in instruments won’t hurt human health or the environment.

6. EN 556 – Sterilization Standards

Needed to label instruments as “sterile.”

Instruments need to be able to withstand validated sterilization processes such as:

Steam autoclaving

EO (Ethylene Oxide) gas

Gamma irradiation

Rhein Group's Commitment to Quality

Rhein Group follows all of the above and beyond:

In-house quality control labs

Micro-inspections for blade edge accuracy

Batch traceability from raw material to finished product

Custom testing based on client region (FDA, CE, etc.)

Conclusion: Cut With Confidence

When it comes to surgery, there’s no margin for error and surgical scissors by Rhein Group are designed to provide none. Whether you are dealing with regular sutures, thin layers of tissue, or intricate neurosurgical incisions, our tools ensure the proficiency that contemporary surgery requires.