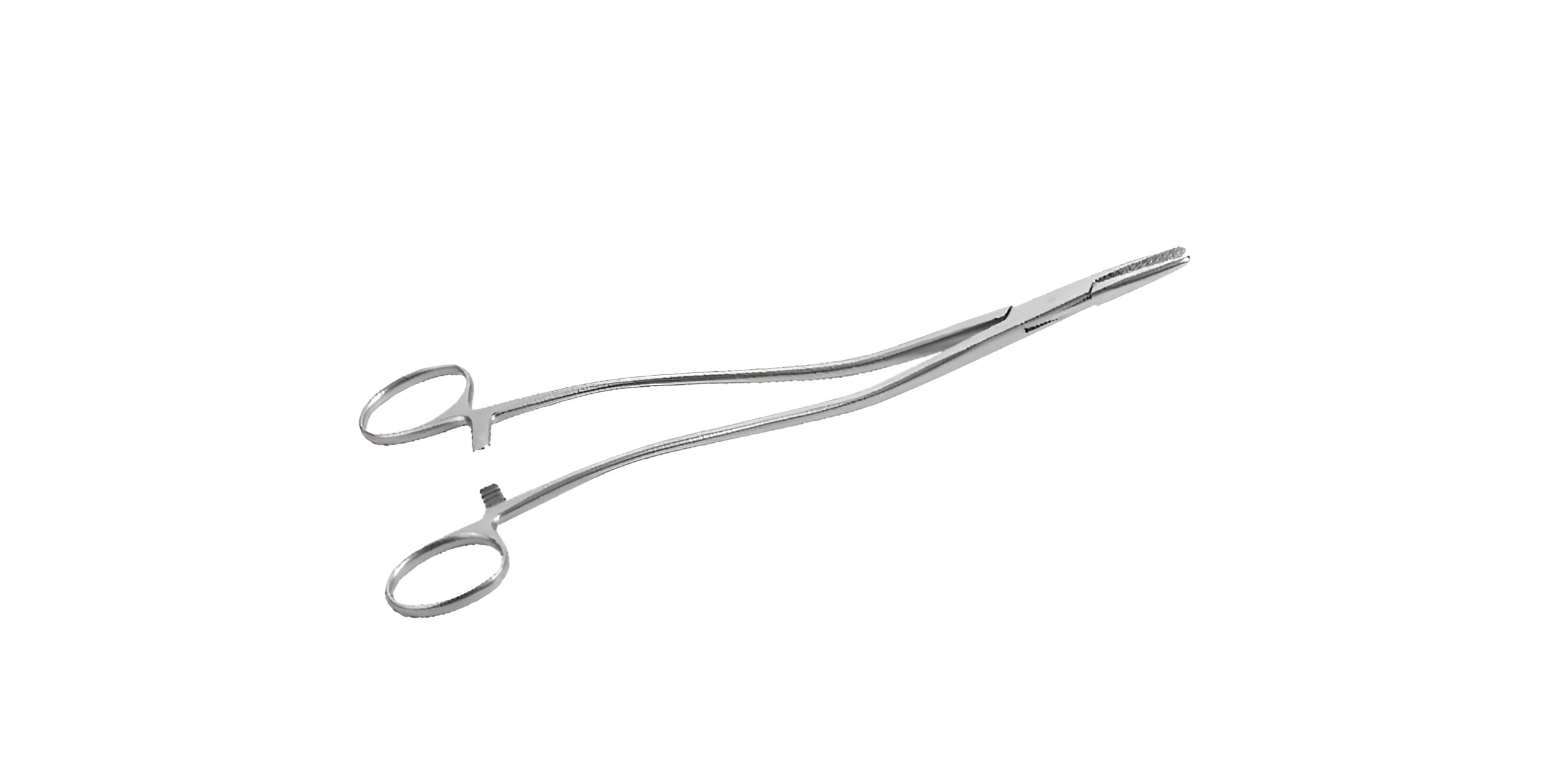

Surgical Needle Holders by Rhein Group: Precision Control in Suturing Precision

Precision is everything in the complex world of surgery—particularly when it comes to suturing. For one, a tight, secure stitch can be the difference between effortless healing and complications.

That’s where needle holders are used. At Rhein Group, we design needle holder forceps with surgeon-centric design, providing stability, accuracy, and comfort even in the most challenging procedures.

In this article, we will discuss the various types of needle holders by Rhein Group, their applications, innovations, and what makes our instruments stand out on the international surgical platform.

Why Needle Holders are Critical in Surgery

A needle holder is more than a clamp—it’s a surgeon’s link to healing. Its sole function is straightforward but vital:

-

Securing and holding a surgical needle

-

Exerting firm control during suturing

-

Allowing delicate yet firm manipulation of needles

Rhein Group designs needle holders that provide optimal tactile feedback while limiting surgeon hand fatigue, a balance important in lengthy surgeries or precise suturing.

Anatomy of a Needle Holder

Each needle holder instrument from Rhein Group is designed with:

-

Precision-aligned jaws: Provide maximum needle grip with no slippage.

-

Ergonomic handles: Minimize strain for extended use.

-

Ratchet locking mechanisms: Provide positive locking with very little hand pressure.

Self-righting needle holder technology is found in many Rhein models, automatically realigning the needle for efficient, smooth suturing.

Types of Needle Holders Offered by Rhein Group

|

Needle Holder Type |

Best Use |

|

Bozeman needle holder |

OB-GYN procedures, deep suturing |

|

Heaney needle holder |

Gynecologic and pelvic surgeries |

|

DeBakey needle holder |

Vascular suturing or pediatric surgeries |

|

Ryder needle holder |

Cardiovascular and delicate surgeries |

|

Olsen-Hegar |

Cutting sutures mid-procedure in Orthopedic setting. |

|

Castroviejo needle holder |

Micro surgery and ophthalmology |

Each of the instruments is meticulously designed for specialized surgical disciplines, whether cardiovascular, orthopedic, gynecologic, or laparoscopic procedures.

Special Feature: Artery Forceps and Needle Holder Combo

There are instances where efficiency calls for multi-functionality.

Our artery forceps and needle holder instruments come together:

-

Hemostatic clamping force

-

Accurate needle manipulation for quick suturing

This is especially beneficial in trauma surgery or emergency procedures where time is of the essence.

Needle Holder Applications: Accuracy Beyond the Operating Room

Needle holders are mostly reserved for surgery suturing, but their uses go beyond that:

-

Plastic and reconstructive surgery: Delicate, cosmetic sutures.

-

Orthopedics: Fixing hard, fibrous tissues.

-

Cardiovascular surgery: Working with ultra-fine needles.

-

Veterinary surgery: Specialized suturing for animals.

-

Training laboratories: Suturing practice.

Whether in human medicine, animal care, or surgical training, Rhein’s needle holder forceps provide control and confidence.

Shine on Specialty Needle Holders

1. Bozeman Needle Holder

-

Long shank, curved shape.

-

Best suited for deep suturing in gynecological surgeries.

2. Heaney Needle Holder

-

Slightly angled jaws for pelvic surgery.

-

Provides unmatched control in confined spaces.

3. DeBakey needle holder

-

Fine, delicate serrated jaws with ratchets

-

For pediatric and microvascular procedures.

4. Ryder Needle Holder

-

Slim jaws with tungsten inserts.

-

Delicate care for cardiovascular and nerve repair procedures.

Needle Holder Price Guide

Rhein Group provides high-quality instruments at affordable prices, delivering value without compromising quality.

Prices depend on material, handle style, and customizations.

Bulk orders, OEM logo, and customized set are available. Contact our Sales Team for further information.

Why Choose Needle Holders by Rhein Group?

-

German Stainless Steel Construction: For strength and sterilization resistance.

-

ISO 13485, CE Marking, MDR and FDA Compliance: Guaranteed global quality standards.

-

Ergonomic Innovations: Such as self-righting functionality for self-needle alignment.

-

Extensive Range: From laparoscopic needle holders to dainty micro-needle applications.

All needle holders are thoroughly tested for jaw alignment, ratcheting, and grip force to be reliable in the operating suite.

Testimonials in the Field

Global Manufacturing Standards for Surgical Instruments

1. ISO 13485: Medical Devices Quality Management Systems

Purpose: Defines requirements for a medical device-specific quality management system.

Why it matters: Guarantees that equipment complies with regulatory requirements, patient safety, and uniform quality.

How it’s implemented:

-

Documentation of production and design processes

-

Risk management and traceability systems

-

Regular internal and third-party audits

2. CE Marking (European Conformity)

Required for: Sale of surgical instruments in the European Union (EU) and European Economic Area (EEA).

Indicates: Conformity to EU Medical Device Regulations (MDR).

Ensures:

-

Biocompatibility

-

Sterilization validation

-

Safety during intended use

3. FDA 21 CFR Part 820 (U.S. FDA Quality System Regulation)

Applicable to: Manufacturers selling in the United States.

Aims at: Quality assurance, validation, and complaint handling.

What it covers:

-

Device Master Records (DMRs)

-

Corrective and Preventive Actions (CAPA)

-

Inspection and testing procedures

4. ASTM & ISO Material Standards

ASTM F899: Standard for stainless steel used in surgical instruments.

ISO 7153-1: Defines corrosion-resistant steel and alloys for instruments.

Rationale: Guarantees materials:

-

Withstand repeated sterilization

-

Don’t corrode, rust, or cause tissue damage

-

Retain sharpness and structural integrity

5. RoHS & REACH Compliance (European Market)

-

RoHS: Prohibits use of hazardous materials in electronics and materials.

-

REACH: Guarantees chemicals used in instruments won’t hurt human health or the environment.

6. EN 556 – Sterilization Standards

Needed to label instruments as “sterile.”

Instruments need to be able to withstand validated sterilization processes such as:

-

Steam autoclaving

-

EO (Ethylene Oxide) gas

-

Gamma irradiation

Rhein Group's Commitment to Quality

Rhein Group follows all of the above and beyond:

In-house quality control labs

Micro-inspections for blade edge accuracy

Batch traceability from raw material to finished product

Custom testing based on client region (FDA, CE, etc.)

Conclusion: Secure Every Stitch with Rhein Precision

When suturing, there can be no substitute for trust. With Rhein Group’s line of expertly crafted needle holders, you have tools that provide precision, control, and performance—at every knot you tie, stitch you set, and wound you close.

Discover the entire Rhein Group line and find the needle holder that’s right for your practice.